Learn about the pros and cons of all of the Kreg Pocket hole jigs so you can pick the right one for you.

Whether you are looking to buy your first Kreg pocket hole jig or ready to upgrade, you need to understand all the features and differences to pick the right one for you and your shop!

So I partnered with Kreg Tools to share this comprehensive guide to help you pick out the best Kreg pocket hole jig.

Below you can see all the differences between the Kreg 300 Series (310 & 320 pocket hole jigs), XL, 520Pro, 720 and 720Pro pocket hole jigs.

This post may contain affiliate links. As an Amazon Associate I earn from qualifying purchases. Click here to read my full disclosure policy.

Table of contents

What is a Pocket Hole Jig?

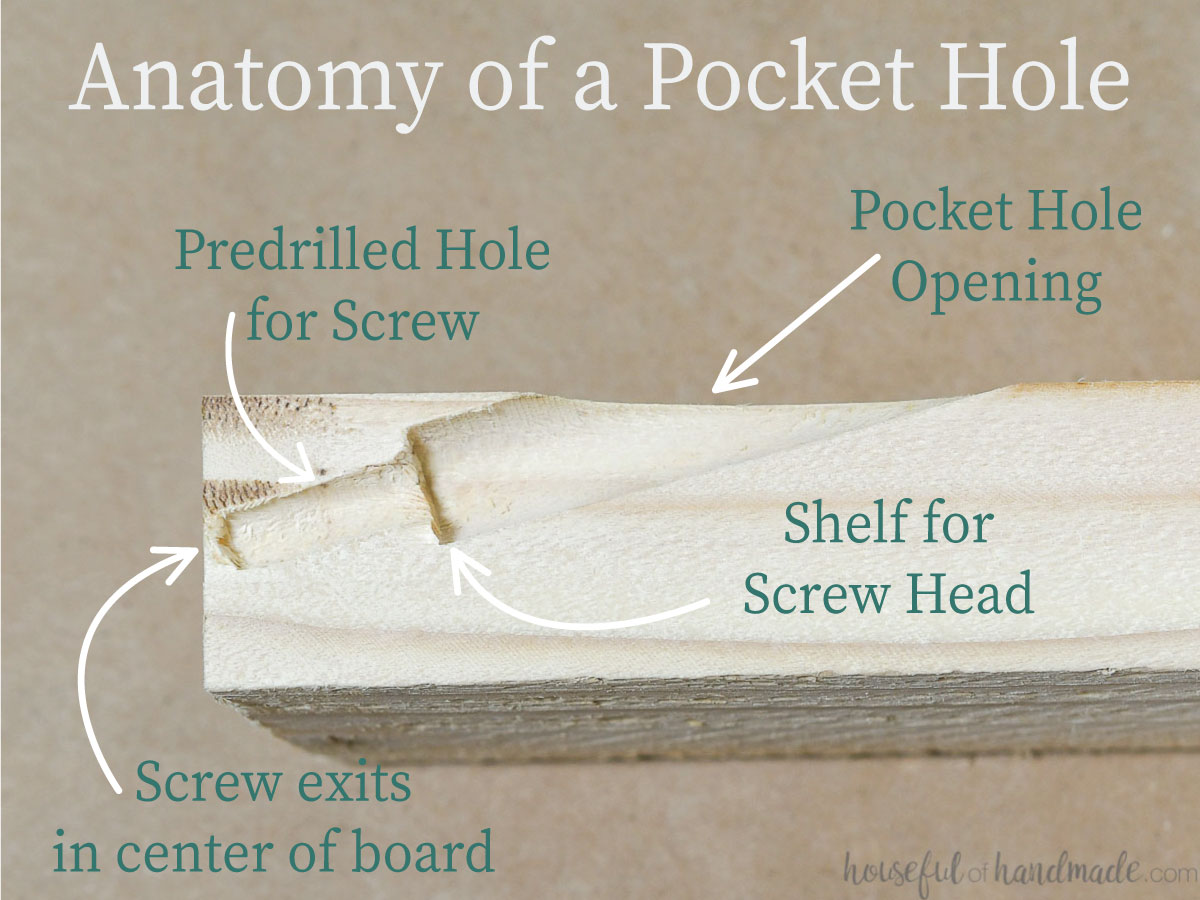

A pocket hole is a type of joinery where you drill a hole at a slight angle into one board. Then you can drive a screw through that hole into a joining board.

The screw pulls the boards tight and creates a strong hold. The angle and placement of the pocket hole ensures the screw comes out of the first board right in the center.

That is where the Kreg pocket hole jig comes in!

A pocket hole jig makes it fast and easy to drill pocket holes in any wood. It creates the perfect angle and placement of your pocket hole.

The Kreg jig also predrills a pilot hole stopping right before the end of your board, while creating a shelf to stop the screw head from going in too far.

Can you create a pocket hole without a jig?

Yes you can. But a pocket hole jig takes the guesswork out of the angle and depth you need to drill for your pocket holes.

And since there is a Kreg Jig to fit any budget, it just makes sense to add one to your shop so you can build strong, beautiful projects faster!

Features of the 300 Series Jigs

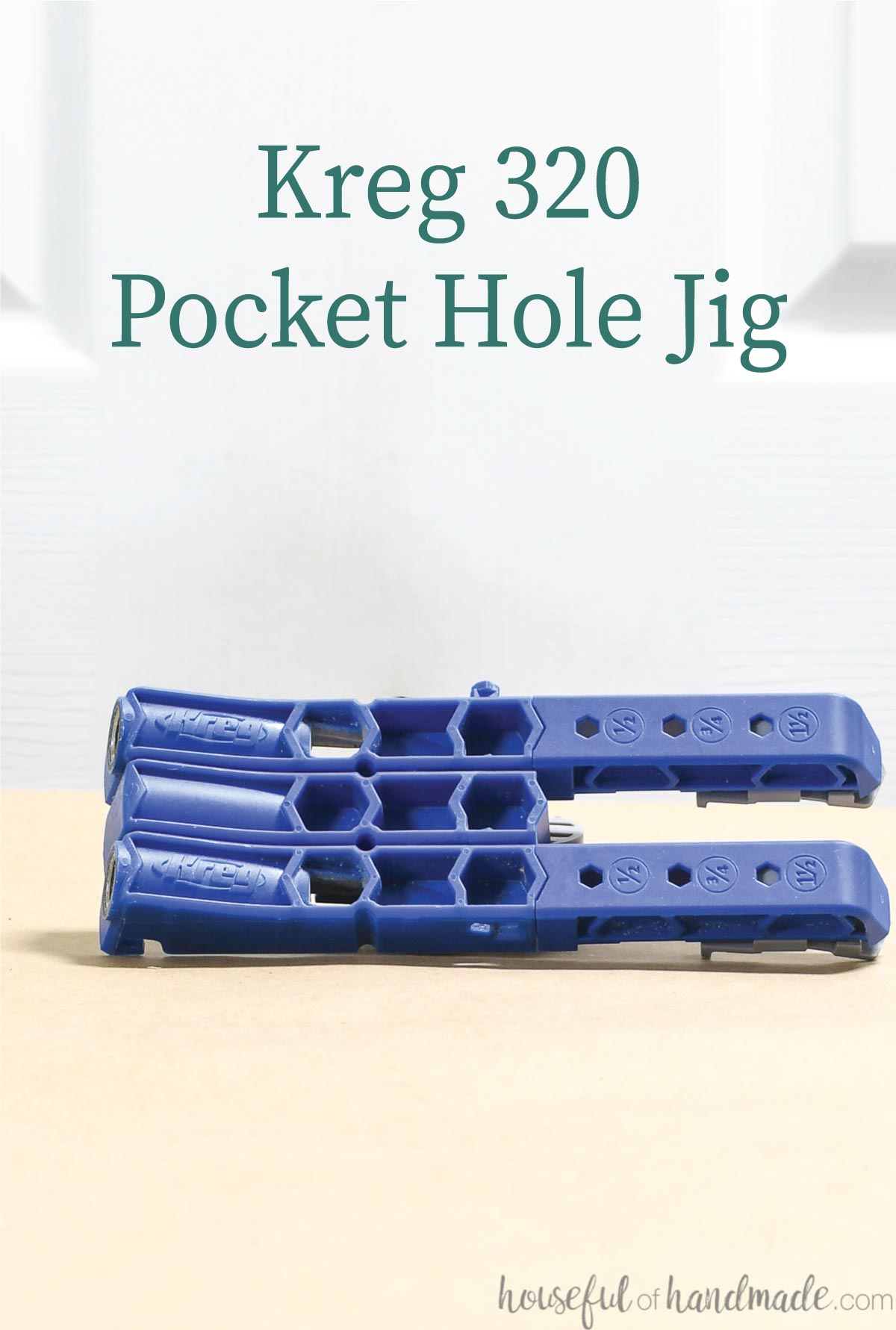

The 300 Series jig is a great portable jig for small spaces, beginner woodworkers, and repairs. Learn how to use the Kreg 300 series pocket hole jig here.

If you plan to make a lot of pocket hole jigs (like for building your own cabinets), it will be more time consuming with this jig and I would recommend the 520Pro or 720 if your budget allows.

There are 2 different jigs in the 300 Series: the 310 and the 320. The functionality of the jigs is the same. Which 300 Series jig you choose depends on your budget and the additional features you may want.

The differences between the 310 and 320 are based off what comes in the package:

- Both jigs come with

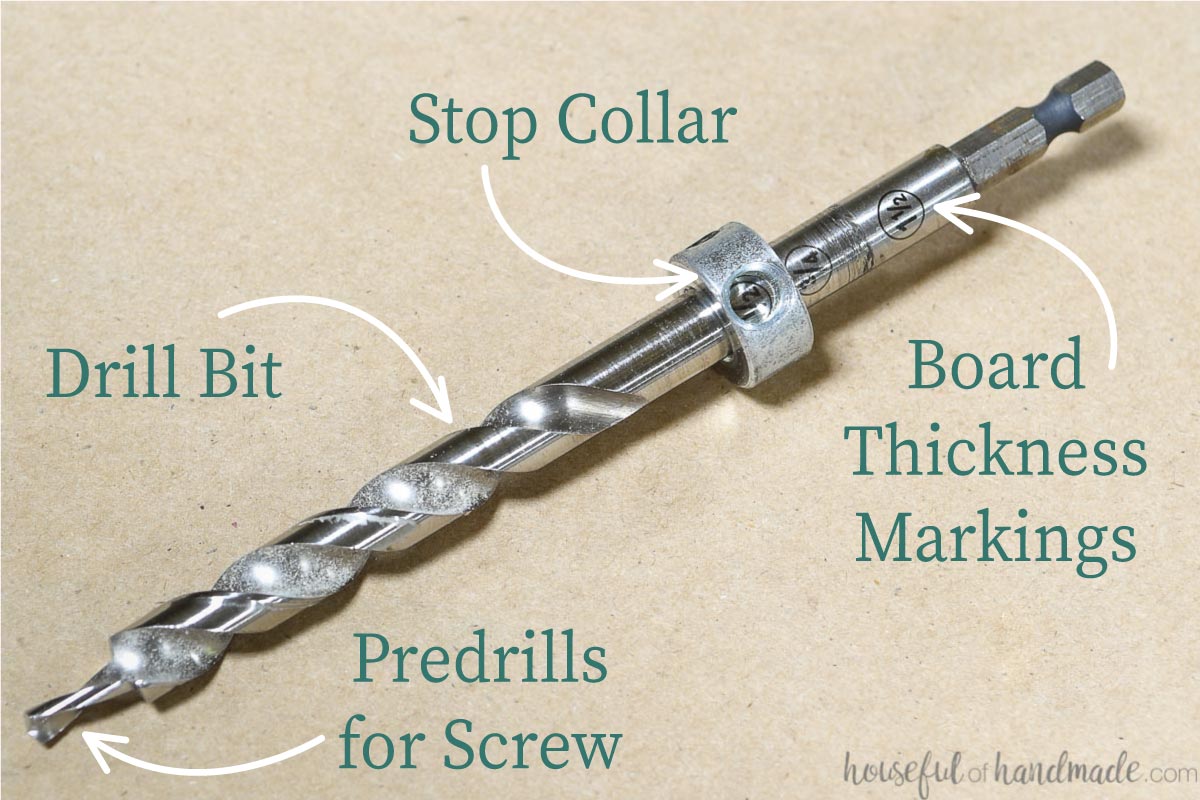

- Drill bit with collar

- 6″ square driver bit

- Material thickness gauge

- 310 comes with

- 1 drill guide

- 320 comes with

- 2 drill guides

- Spacer

- Carrying case

- Sample screws

Jig Size

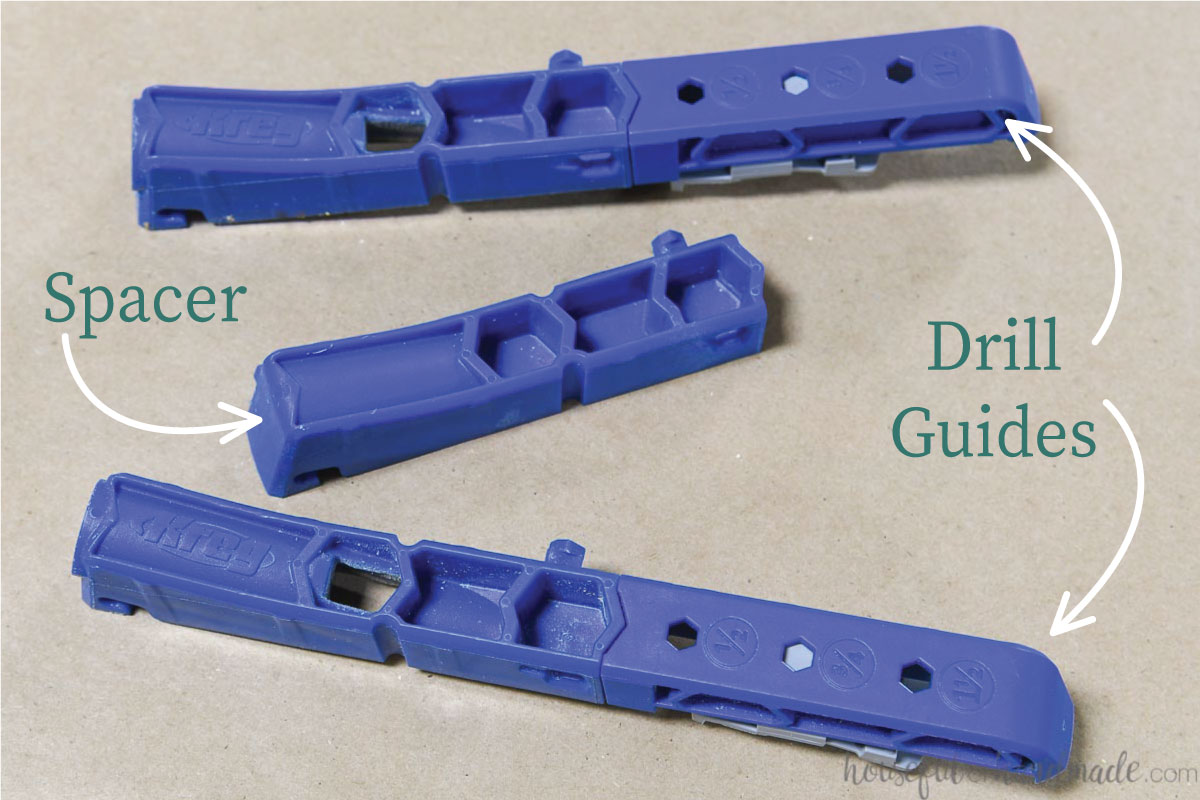

A single drill guide that comes with the 310 series jigs is 1″ wide x 7″ long x 1″ deep. The 320 jig (2 drill guides together with a spacer between) is 2 1/2″ wide x 7″ long x 1″ deep.

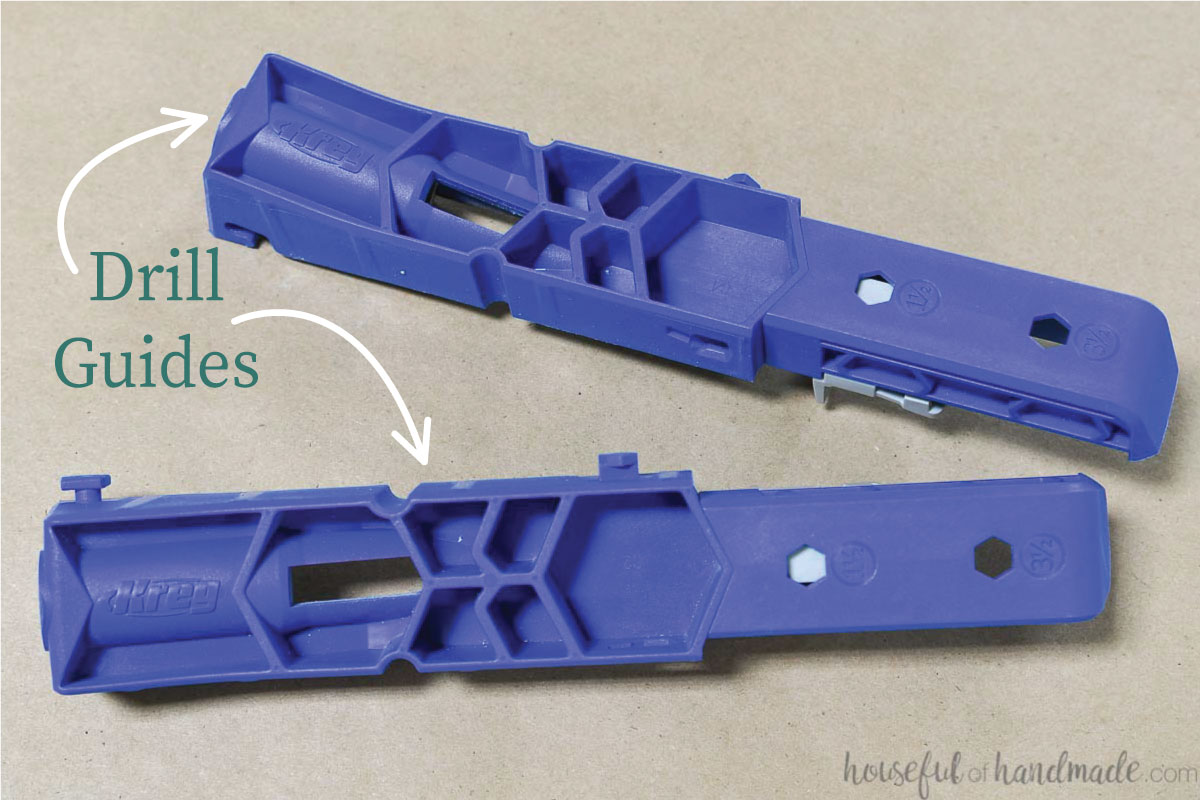

You can use the drill guides individually, or clip them together for easy spacing on small boards.

- For 1 1/2″ wide boards (1×2 & 2×2) use 2 drill guides with no spacer

- For 3 1/2″ wide boards (1×4 & 2×4) use 2 drill guides with a spacer

- For long boards, space pocket holes 5/8″-1 1/2″ away from edge and 6″-8″ apart

Mobility & Clamping

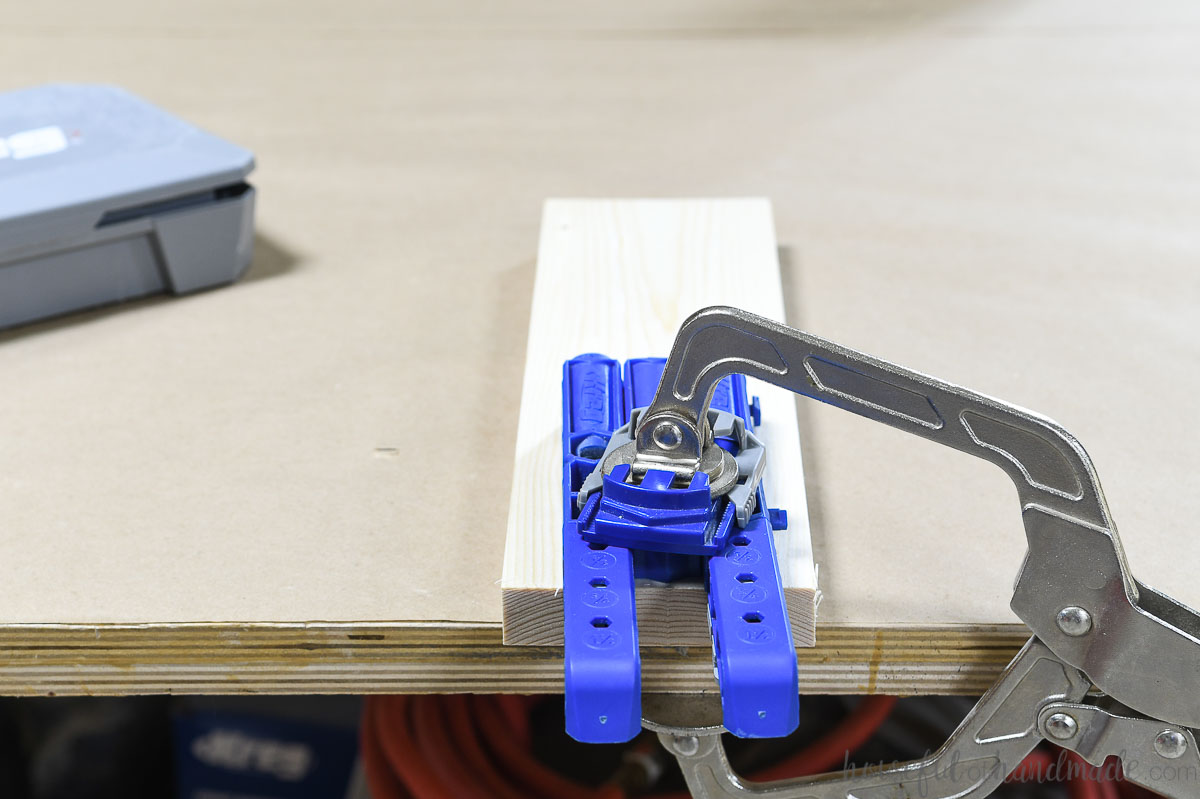

The 300 series jigs are portable pocket hole jigs. They are clamped to the surface of your wood.

These pocket hole jigs require an external clamp to work.

You can attach a Kreg face clamp (I prefer the Automaxx clamp because it automatically adjusts for material thickness) to the jig with the clamp adapter. This will make it faster to move the jig between boards.

Also, if you cannot use a clamp to attach the jig (if doing repairs), you can secure the jig to the workpiece with a screw. Drive the screw through the recess on the sides of the jig or the hole it created when multiple drill guides are connected.

Capacity & Adjustability

The 300 series pocket hole jigs can drill pocket holes in 1/2″ thick to 1 1/2″ thick lumber.

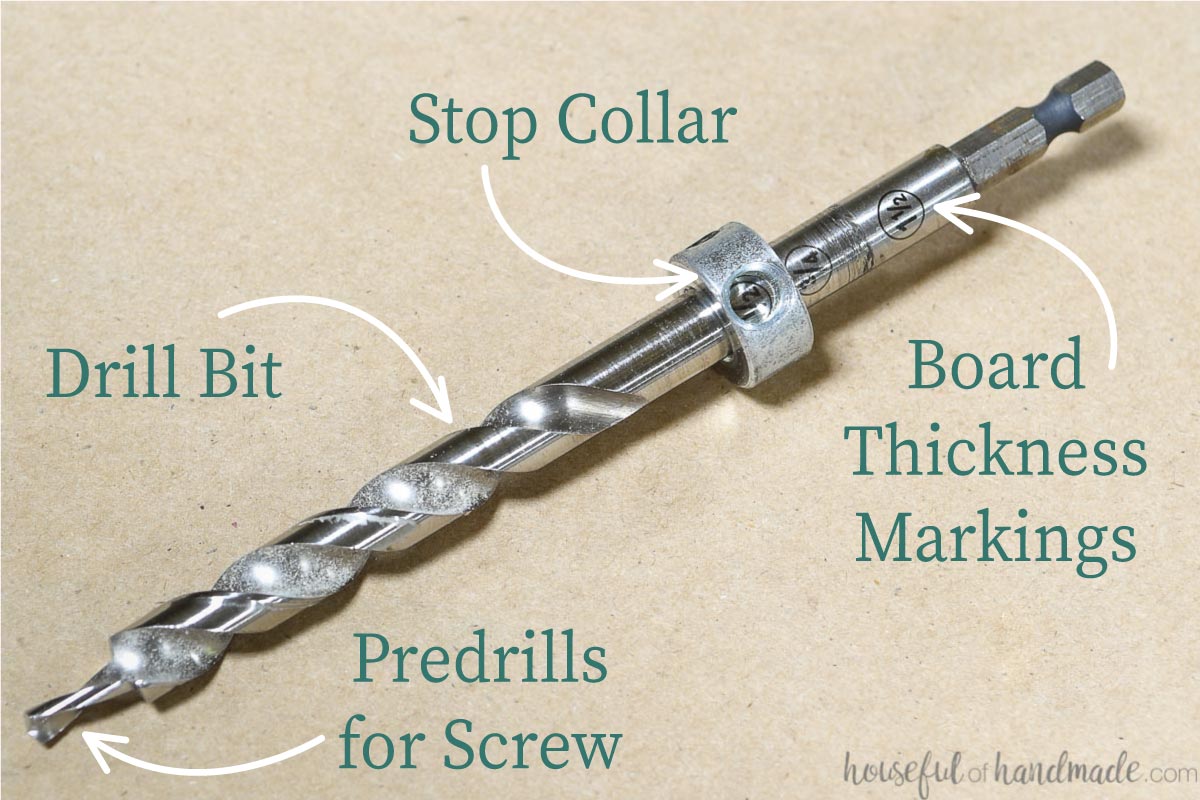

You will need to adjust the material thickness setting on the drill bit and jig before you can drill pocket holes. This will ensure your pockets holes are properly spaced and the hole goes just to the end of the board.

To adjust the material thickness on the drill bit: loosen the screw on the side of the collar with the hex wrench on the side of the material thickness gauge.

Slide the drill bit collar until you see the appropriate thickness marking inside the hole in the collar. Tighten the screw.

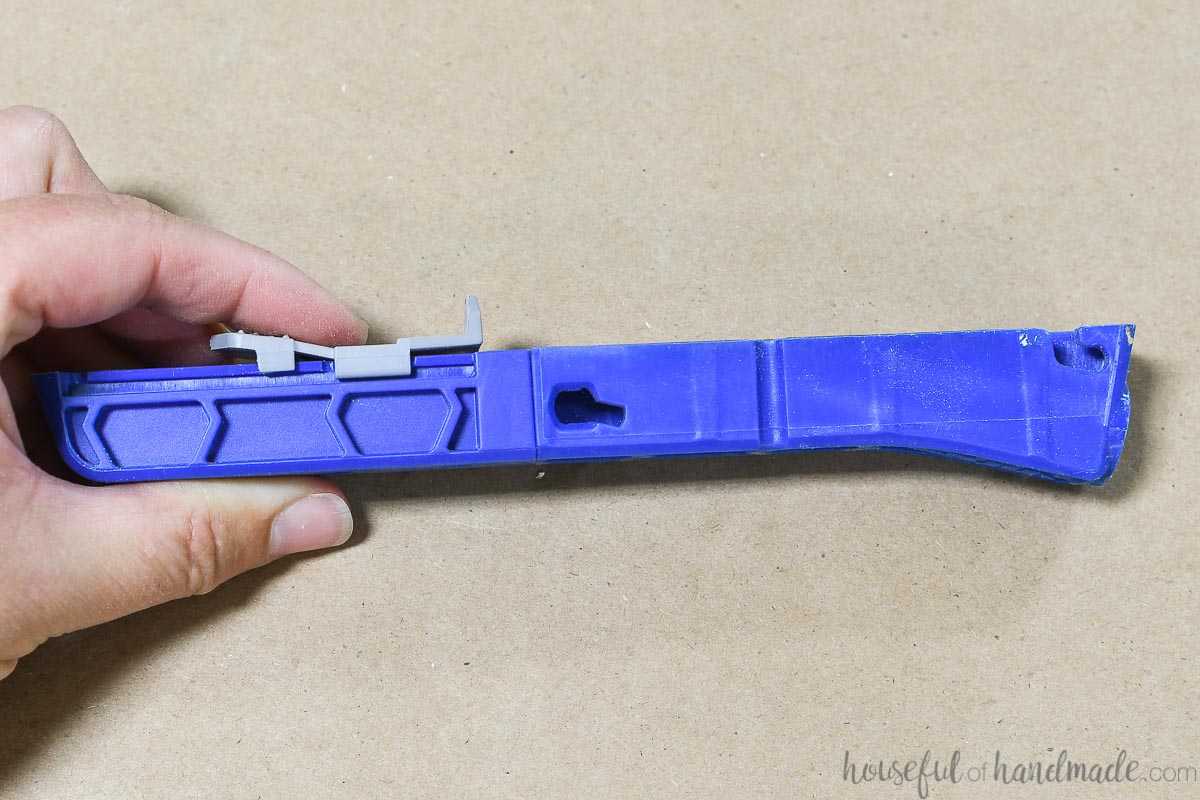

To adjust the material thickness on the jig: slide the gray tabs (called material thickness stops) on the back of the drill guide to the right thickness.

There are preset stops at 1/2″, 3/4″ and 1 1/2″ on the drill bit and jig. Use the material thickness gauge to determine the thickness setting needed.

If your material falls between the 3/4″ and 1 1/2″ markings on the gauge, you can still use the 310 or 320 pocket hole jigs. Just set your drill bit and jig to the 3/4″ preset. Then use 1 1/2″ long screws to join your material instead of the 1 1/4″ recommended for 3/4″ thick material.

Optional Accessories

The 300 series is not compatible with the micro jig or plug cutter attachments.

However, there is an optional expansion pack that includes 1 drill guide and 1 spacer. This will allow you to create multiple pocket holes faster with this simple jig.

Things to Build with the 310 & 320 Jigs

Features of the XL Jig

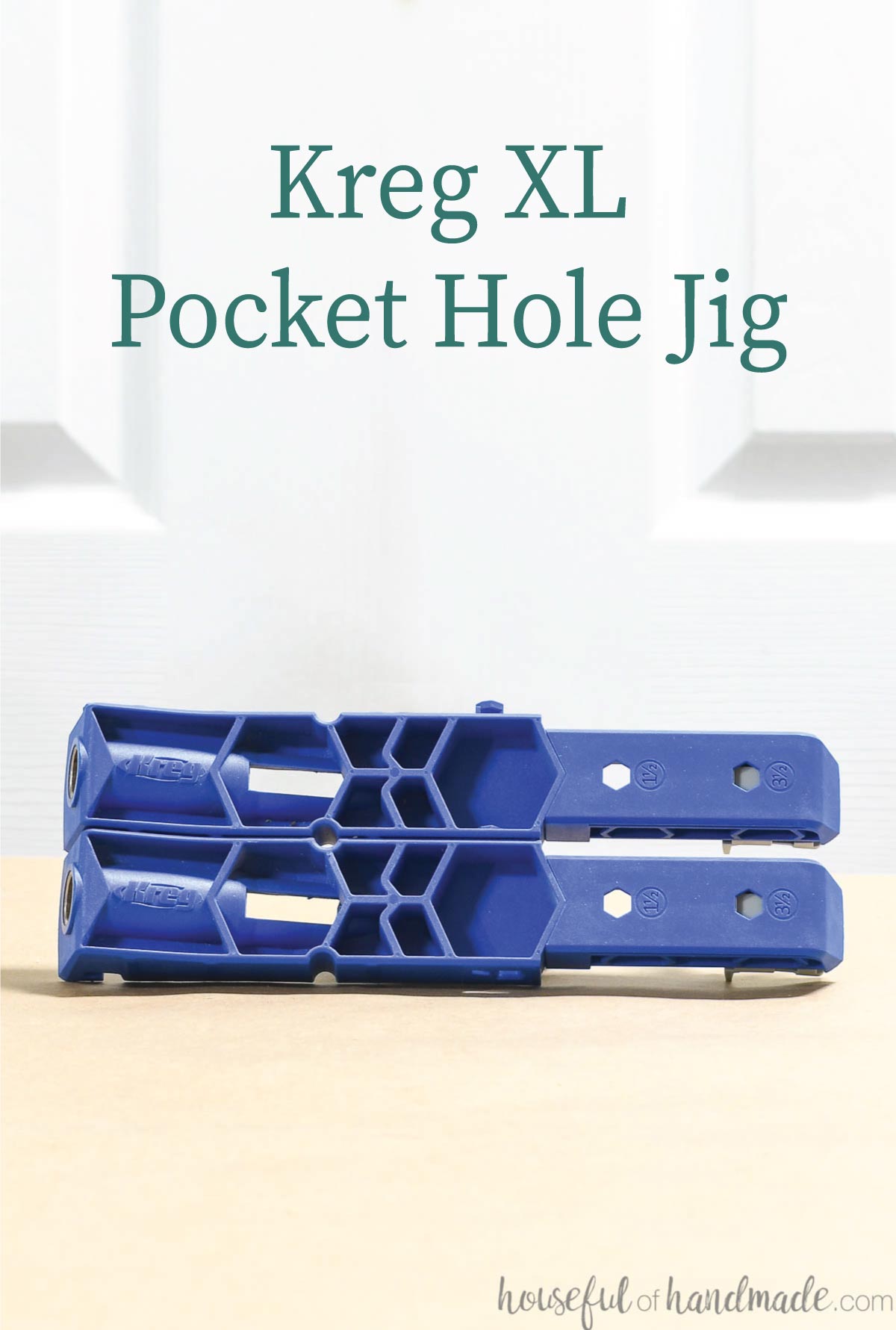

The XL jig looks just like the 300 series jig, but is much bigger. The XL jig is the only Kreg pocket hole jig that allows you to make pocket holes in 3 1/2″ thick material (4×4 boards).

The functionality of the Kreg XL jig is the same as the 300 series but with larger drill guides and presets for thicker material.

The Kreg XL jig comes with:

- Jig with 2 drill guides

- XL drill bit & collar

- 6″ XL square driver bit

- hex wrench

- clamp adapter

Jig Size

A single XL drill guide is 1 3/4″ wide x 9″ long x 1 1/4″ deep. When you clip 2 drill guides together it is 3 1/4″ wide x 9″ long x 1 1/4″ deep.

This XL pocket hole jig includes 2 drill guides. You can use the drill guides individually, or clip them together so they are perfectly spaced to use on 3 1/2″ wide boards.

Mobility & Clamping

The XL jig is a portable pocket hole jig. You will clamp it to the surface of your wood.

It requires an external clamp to work. You can use the clamp adapter to hold your clamp on the jig while working.

Also, if you cannot use a clamp to attach the jig, you can secure the jig to the workpiece with 1 or 2 pocket hole screws. Drive screws through the recesses on the sides of the jig to secure or through the hole created when the drill guides are connected.

Capacity & Adjustability

The Kreg XL pocket hole jig can drill pocket holes in 1 1/2″ thick to 3 1/2″ thick lumber.

You will need to adjust the material thickness setting on the drill bit and jig before you can drill pocket holes. This will ensure your pockets holes are properly spaced and the hole goes just to the end of the board.

To adjust the material thickness on the drill bit: loosen the screw on the side of the collar with the included hex wrench.

Slide the drill bit collar until you see the appropriate thickness marking inside the hole in the collar. Tighten the screw.

To adjust the material thickness on the jig: slide the gray tabs (called material thickness stops) on the back of the drill guide to the right thickness.

The tabs should click into the preset markings and you will see the gray show through on the front of the jig in the appropriate thickness.

There are preset stops at 1 1/2″ and 3 1/2″ on the drill bit and jig.

Optional Accessories

The XL does not have any optional accessories.

Things to Build with the XL Jig

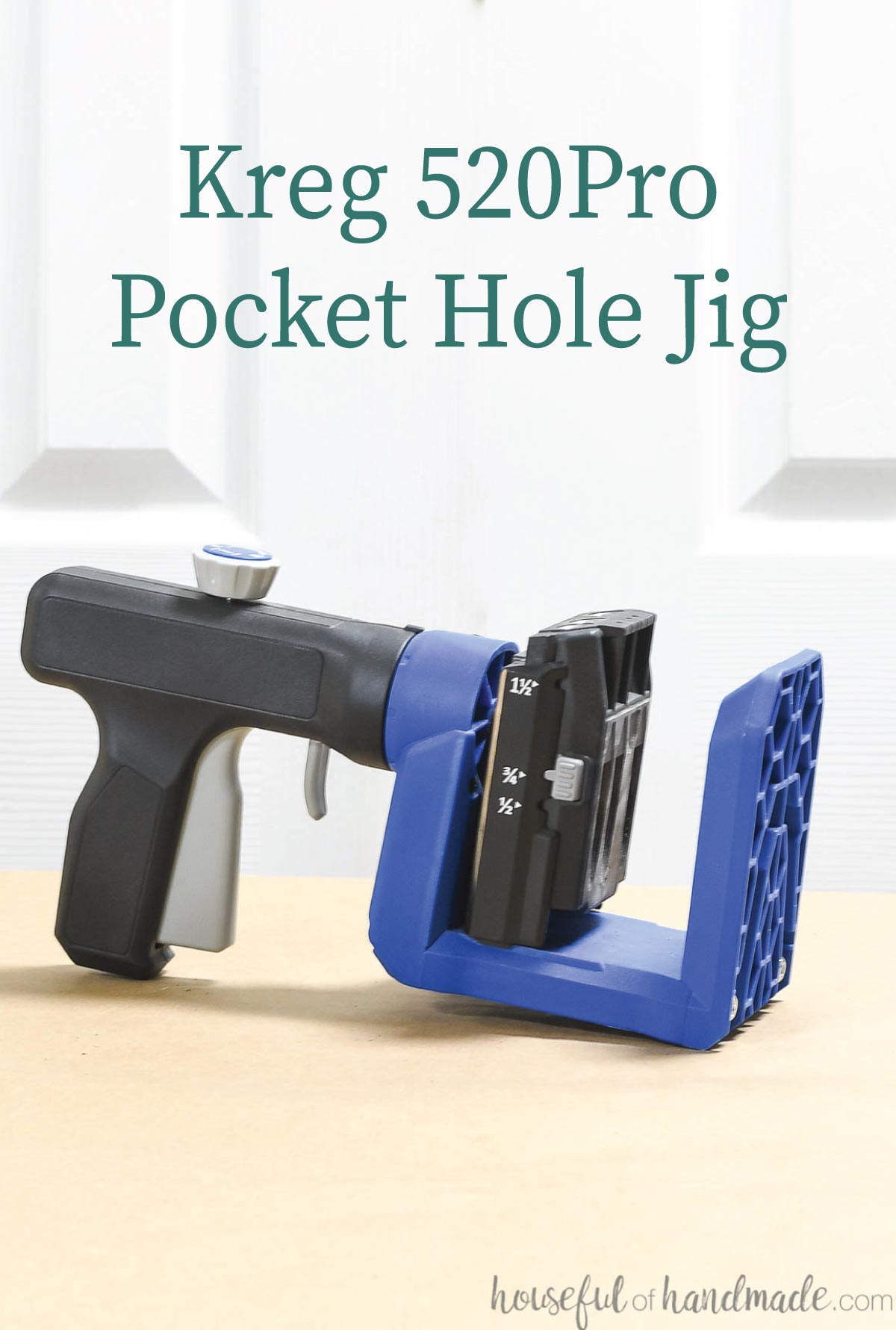

Features of the 520Pro Jig

The 520Pro pocket hole jig is a great pocket hole jig for anyone. It is easy to use for beginners, and can make quick work of projects with lots of pocket holes.

The biggest con of the 520Pro is that it cannot be adjusted to non-standard board thicknesses. You can get around this by using standard settings with different screws (see below).

Other downsides are: no dust collection, drill guides cannot be used outside of jig for repairs, and it is not compatible with a plug cutter attachment.

The Kreg 520Pro jig comes with:

- Pocket hole jig

- Drill bit with collar

- 6″ square driver bit

- Material thickness gauge

- 2″ classic face clamp

- 100 pocket hole screws

Jig Size

The 520Pro jig measures 3 1/4″ wide x 10 1/2″ long x 5″ tall.

The compact size makes this jig extremely handy. It is easy to store in a drawer and pull out whenever needed.

Mobility & Clamping

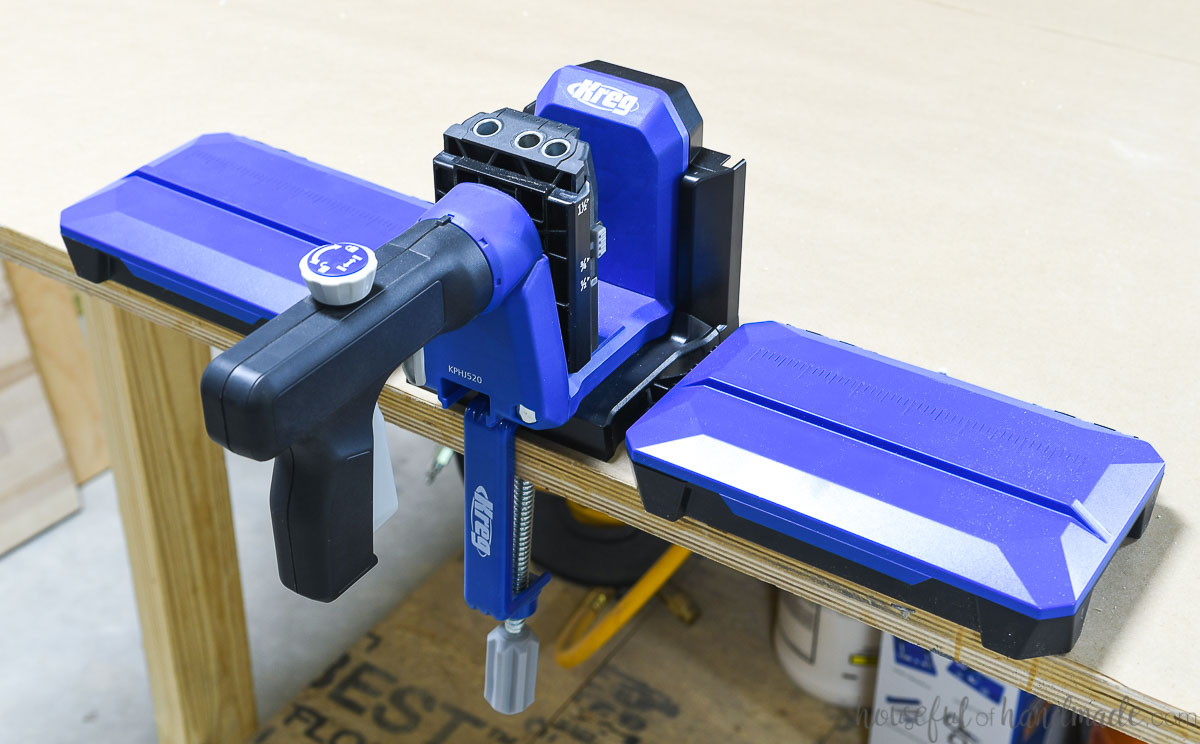

The 520 pocket hole jig is super versatile. It can be both portable or used as a benchtop jig.

If you add the optional Kreg pocket hole jig clamp, you can clamp the jig to your benchtop.

To improve the benchtop capabilities, you can add the optional docking station. This creates a level surface around your pocket hole jig to prevent larger boards from tipping.

The docking station can be secured to your benchtop with screws or the clamp. Then you can quickly remove the jig from it to use as a portable jig again.

The 520 jig is easy to move to your workpiece and clamp down. It has an integrated VersaGrip clamp in the handle.

To secure your board, all you need to do is pump the handle until it is tight. Then pull the trigger to release the board.

You can use the quick reset knob if you are drilling multiple pocket holes in similar thicknesses of material. This prevents the handle from releasing fully so you have less pumping between pocket holes.

The 520Pro can be rotated to drill pocket holes vertically or horizontally. This makes it convenient to use on any board.

The VersaGrip handle also rotates 360 degrees to make it easy to clamp to any boards anywhere.

Capacity & Adjustability

The 520Pro pocket hole jig can drill pocket holes in 1/2″ thick to 1 1/2″ thick lumber.

The drilling guide has 3 holes positioned for use on 1 1/2″ wide, 2 1/2″ wide and 3 1/2″ wide boards without having to reposition the board in the jig.

The drilling guide also has marks to easily center the holes on the boards.

You will need to adjust the material thickness setting on the drill bit and jig before you can drill pocket holes. This will ensure your pockets holes are properly spaced and the hole goes just to the end of the board.

To adjust the material thickness on the drill bit: loosen the screw on the side of the collar with the included hex wrench.

Slide the drill bit collar until you see the appropriate thickness marking inside the hole in the collar. Tighten the screw.

To adjust the material thickness on the jig: slide the drilling guides up or down by pressing the gray tabs on the side and locking it into places at the appropriate thickness setting.

There are preset stops at 1/2″, 3/4″ and 1 1/2″ on the drill bit and jig.

If your material falls between the 3/4″ and 1 1/2″ markings on the gauge, you can still use the 520Pro pocket hole jigs. Just set your drill bit and jig to the 3/4″ preset. Then use 1 1/2″ long screws to join your material instead of the 1 1/4″ recommended for 3/4″ thick material.

Optional Accessories

The 520Pro is compatible with the docking station. The docking station includes:

- Material support wings

- Adjustable stop for lining up pocket holes in similar stock

- Jig clamp

The 520Pro is also compatible with the micro-pocket hole jig to the micro pocket hole guide. This allows you to create smaller holes that are great for small projects and thinner boards.

Things to Build with the 520Pro Jig

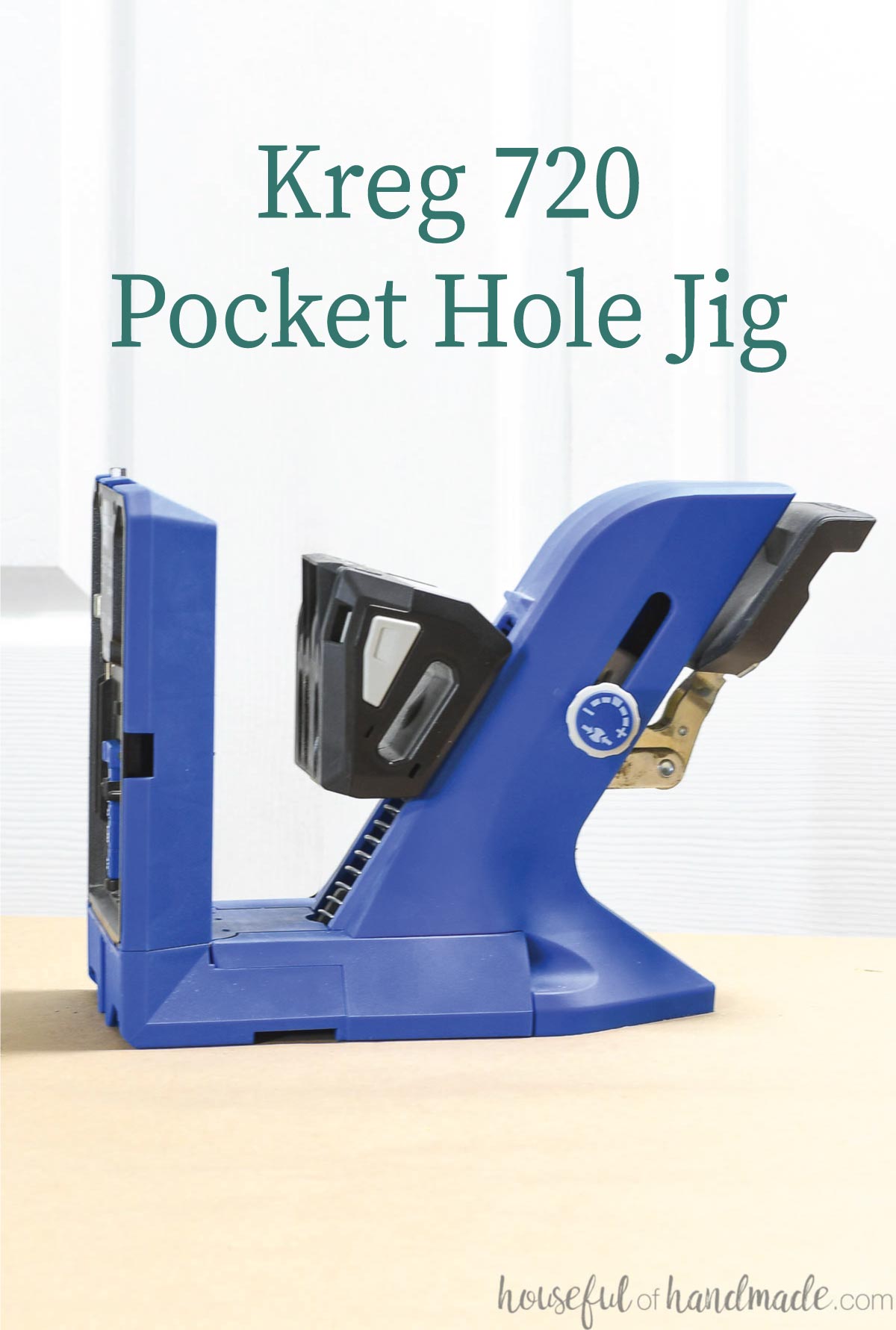

Features of the 720 and 720Pro Jigs

The 720 Series pocket hole jig is the ultimate pocket hole jig for woodworkers. It comes loaded with features to get the most functionality from your pocket holes. Learn how to use the Kreg 720 jig here.

Almost all the cons of the 520Pro jig are eliminated with this jig. It can be adjusted to any lumber thickness between 1/2″ and 1 1/2″, has dust collection and is compatible with the plug cutter.

The only cons is that you cannot use the drill guide independently for repairs.

The differences between the 720 and 720Pro jigs is based on what it comes with:

- Both jigs come with

- Pocket hole jig

- Drill bit with collar

- 3″ & 6″ square driver bit

- Material thickness gauge

- Dust collection blade & adapter

- 60 Pocket hole screws

- 720Pro also comes with

- Docking station

- Jig clamp

- 100 additional pocket hole screws

Jig Size

The Kreg 720 jig measures 4 1/2″ x 12 1/2″ x 8 1/2″.

One of the best features of the 720 jigs is the onboard storage. The back of the jig has slots to store your drill bit, both driver bits, and the thickness measuring guide/hex wrench.

Mobility & Clamping

The 720 jig is a benchtop jig. You can secure it to the bench with the jig clamp (optional with the 720 or included with the 720Pro).

You can use it with or without the docking station. The docking station has wings on the side that keep the material in line with the base of the jig to prevent tipping.

These docking station wings offer additional storage. Plus they can fold up not in use and secure to the sides of the jig.

While the 720 is considered a benchtop jig, it is small enough to move around your shop.

The 720 pocket hole jig can be using in both a vertical and horizontal orientation to make drilling pocket holes in any lumber easier.

Capacity & Adjustability

The 720 pocket hole jig can drill pocket holes in 1/2″ thick to 1 1/2″ thick lumber.

The drilling guide has 3 holes positioned for use on 1 1/2″ wide, 2 1/2″ wide and 3 1/2″ wide without having to reposition the board in the jig.

The drilling guide also has marks to easily center the holes on the boards.

With this pocket hole jig, you only need to adjust the material thickness setting on the drill bit. I love having a second drill bit available so I can keep one set for 3/4″ and one for 1 1/2″ (the most used wood thicknesses).

The Automaxx clamp automatically sets the drill guide to the perfect setting for the material thickness.

This will ensure your pockets holes are properly spaced and the hole goes just to the end of the board.

To adjust the material thickness on the drill bit: loosen the screw on the side of the collar with the included hex wrench.

Slide the drill bit collar until you see the appropriate thickness marking inside the hole in the collar. Tighten the screw.

There are preset stops at 1/2″, 3/4″ and 1 1/2″ on the drill bit.

If you are using materials other than these standard thicknesses, place the drill bit into the accessory storage on the back of the jig. Then loosen the collar and move it up or down the drill bit to line up with the thickness markings next to it. Tighten the screw.

No need to adjust the material thickness on the jig! Just clamp the material in the jig with the Automaxx handle and it automatically adjusts to the correct thickness.

The jig can hold material up to 1 1/2″ thick.

Optional Accessories

The 720 series jig is compatible with the docking station. The docking station is included with the 720Pro, but you can also purchase it separately if you want to add it later.

You can change out the drill guide on your 720 pocket hole jig to the micro pocket hole guide. This allows you to create smaller holes that are great for small projects and thinner boards.

The 720 is also compatible with the plug cutter. This allows you to cut custom plugs to fill your pocket holes.

Things to Build with the 720 & 720Pro Jigs

Kreg Jig Comparison Video

If you prefer to watch, I reviewed all the differences between these Kreg jigs in a video too!

Pocket Hole Jig Comparison Chart

| 300 Series | XL | 520Pro | 720 & 720Pro | |

|---|---|---|---|---|

| Size | Up to 2 1/2″ x 7″ x 1″ | 3 1/2″ x 9″ x 1 1/4″ | 3 1/2″ x 10 1/2″ x 5″ | 4 1/2″ x 12 1/2″ x 8 1/2″ |

| Carrying Case | Only 320 | – | – | 720Pro folds up |

| Accessory Storage | Only in 320 case | – | In optional docking station | Built in |

| Mobility | Portable | Portable | Portable or Bench top w/optional docking station | Bench top |

| Clamping | External Clamp | External Clamp | VersaGrip Handle | Automaxx Clamping |

| Capacity | 1/2″ – 1 1/2″ | 1 1/2″ – 3 1/2″ | 1/2″ – 1 1/2″ | 1/2″ – 1 1/2″ |

| Adjustability | Presets at 1/2″, 3/4″ and 1 1/2″ | Presets at 1 1/2″ and 3 1/2″ | Presets at 1/2″, 3/4″ and 1 1/2″ | Can be adjusted to any thickness |

| Thickness Setting | Manual | Manual | Manual | Automatic |

| Dust Collection | – | – | – | Yes |

| Good for Repairs | Yes | Yes | – | – |

| Available Plug Cutter | – | – | – | Yes |

| Available Docking Station | – | – | Yes | Included with 720Pro |

| MSRP | $21.99 / $39.99 | $59.99 | $99.99 | $129.99 / $149.99 |

| BUY NOW | BUY NOW | BUY NOW | BUY NOW |

And if you have any questions, please leave a comment and I will answer it there.

Happy Pocket-Hole-Jig Drilling!

Thank you to Kreg Tools for sponsoring this post. I only recommend products that I use and love and all opinions are 100% my own. Click here to read my full disclosure policy.